Topics Covered

Api 620 Code Free Shipping

- Atmospheric Tanks

- Tank Site, Foundation Design and Construction

- Preventing Bottom Leaks, Tank Settlement

- Materials - Carbon Steel, Aluminum, Stainless

- Design, Sample Problems, Heated Tanks

- External/Internal Pressure, Seismic, Other Loads

- Nozzles and Roof Types

- Fabrication (Shop Work)

- Erection, Welding Requirements

- Testing and Tolerances

- Inspection, Radiography, Ultrasonic

- Welding Requirements

- Marking, API Monogram

- Documentation, Special Service Standards

- Existing Tank Evaluation, Inspection, Repair, Alteration and Reconstruction

- Failures Leading to these Requirements

- Organizations that May Use the Standard

- Definitions of Authorized Inspector, Storage Tank Engineer

- Evaluation to Determine Suitability for Continued Use

- How to Evaluate and Keep Bottoms Leak Free

- Brittle Fracture Considerations

- Inspection and Required Frequency

- Repair and Alteration Requirements

- Internal Inspection Timing Optimization

- Low Pressure Storage Tanks

- Refrigerated and Cryogenic (Such as LNG) Tanks

- Smaller tanks such as oilfield production tanks and UL tanks

Day One

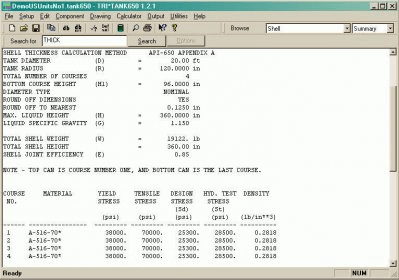

After a quick review of this code, it is readily apparent that API 620 is a bit more technologically advanced than its close cousin API 650. The main difference, as mentioned earlier, is that this code has a higher range of design pressure (up to 15 psig). API 620 is different from API 650 in a number of other ways. For example, API 620. The API Std 650 standard published by the American Petroleum Institute (API) is designed to provide the petroleum industry with welded steel tanks for use in the storage of petroleum products and other liquid products commonly handled and stored by the various branches of the petroleum industry.

Api 620 Code Free

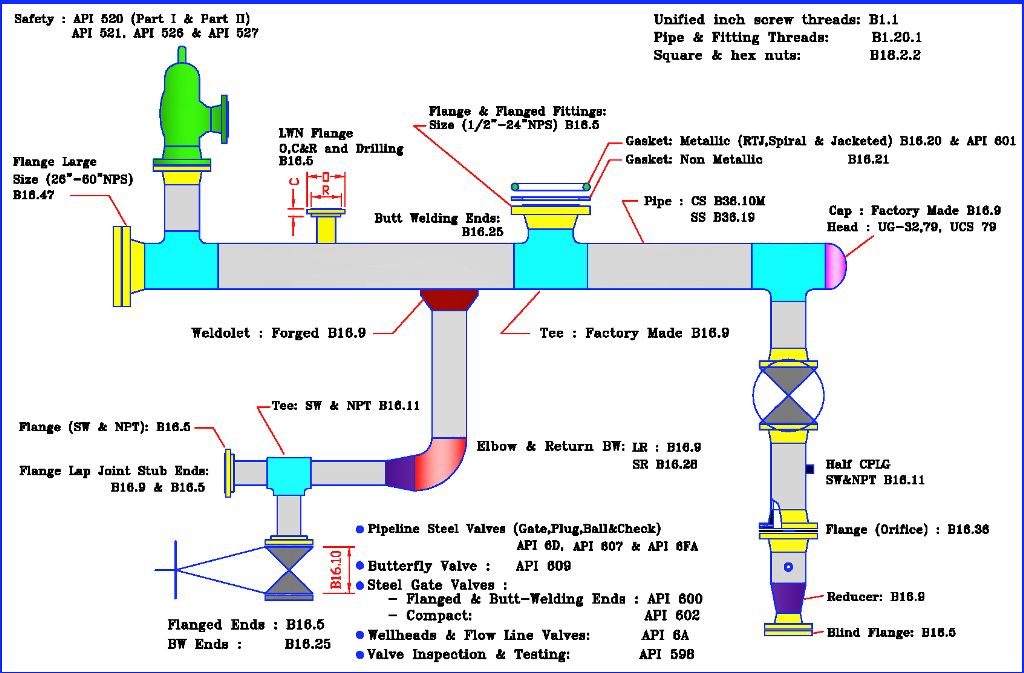

API Standard 650 for design and construction of new storage tanks. Even if you only deal with existing tanks, you must be familiar with API 650 for installing items in existing tanks, such as new nozzles, and requirements not included in the standards for existing tanks. Also presented are tank type selection for various products, insulation for heated tanks, when to use shop fabricated tanks and other items not covered in API 650 but essential for anyone working with tanks.

Api 620 Code Free Pdf

Day Two

Api 620 Code Free Online

API Standard 653 for tank inspection, repair, alteration and reconstruction. An exercise will be conducted to optimize selection of tanks for internal inspection. The required inspection frequency and what to inspect will be covered in detail. How to avoid problems and failures when modifying or repairing old tanks which do not meet current standards. A small amount of time will be devoted to API Standard 620, which deals with low pressure storage tanks, such as tanks with blanketing gas and refrigerated products (butane, propane, LNG, etc.), and smaller tanks such as oilfield production tanks and Underwriters Laboratory tanks.